The Mid-Autumn Festival

The Mid-Autumn Festival

Sep 27, 2023

Every year on the 15th day of the eighth lunar month, in China, it is a day for family reunions and a traditional cultural festival popular among all ethnic groups in the country. Because this day is just the third half of autumn, so named "Mid-Autumn Festival".

It is said that the moon on this night is the largest, roundest and brightest, so since ancient times, people have the Mid-Autumn Festival night, and the family together to feast the custom of appreciating the moon, the daughter-in-law of the mother's home must return to the husband's home on this day, meaning complete and auspicious.

Mid-Autumn Festival originated in ancient times, popular in the Han Dynasty, shaped in the early Tang Dynasty, popular after the Song Dynasty, and the Spring Festival, Qingming Festival, Dragon Boat Festival and known as China's four traditional festivals.

The Mid-Autumn Festival originated from the worship of the sky, and evolved from the ancient autumn festival to the moon. Since ancient times, the Chinese people have the custom of offering sacrifices to the moon, enjoying the full moon, eating mooncakes, watching lanterns, appreciating osmanthus flowers and drinking osmanthus wine on the night of the Mid-Autumn Festival.

After several changes in the thousands of years of inheritance, the spirit of "family reunion" has become the main cultural connotation of today's Mid-Autumn Festival.

On May 20, 2006, the Mid-Autumn Festival was included in the first batch of national intangible cultural heritage list by The State Council. On January 1, 2008, the Mid-Autumn Festival was listed as a national holiday by The State Council.

This "day and night" system continued until the Qing Dynasty. It can be said that "the gift of the evening moon" opened the Mid-Autumn Festival, which is one of the important factors in the formation of a traditional cultural festival. The main activities of the Mid-Autumn Festival revolve around the "moon". In the Mid-Autumn Festival, people play and admire the moon, and a lot of customs related to the moon have been derived, and continue to this day.

Since Tang and Song dynasties, it has become a habit to eat moon cakes on Mid-Autumn Day. The moon cake is shaped like a circle, which symbolizes the circle and is widely welcomed by the people. In the Mid-Autumn Festival, people not only provide moon cakes, eat moon cakes, but also give moon cakes to each other as gifts, which is the good wish of the people for reunion and harmony. Moon cakes are also called "reunion cakes".

On this reunion day, the people return home as scheduled on this day, relatives and friends gather, sit together, eat a "reunion dinner", drink a "reunion wine". This also reflects the belief in the definition of happiness and beauty and the survival of generations in the traditional Chinese agricultural society, which emphasizes family and ethics.

In modern society, there are many kinds of moon cakes, various flavors and fillings, everything, and the packaging of moon cake boxes is also dazzling, exquisite and novel. Every one or two months before the Mid-Autumn Festival, the printing factory is almost all kinds of exquisite mooncake box printing business. In the major shopping malls, filled with exquisite mooncake gift boxes, people will choose their favorite moon cakes, give relatives and friends, bring each other a good meaning and blessing. These mooncake boxes not only carry creativity and beauty, but also inherit people's respect and continuation of traditional culture.

Mooncake box packaging printing will use a variety of printing processes, here we also summarize some printing processes and their characteristics.

UV process

The characteristics of the UV process : on the surface of ordinary offset paper, or BOPP matte film, the screen printing process is used to coat the pattern on the mooncake box, so that the coating area forms a strong contrast with the matte or bright surface. The choice of printing ink also very important.

Bulking process

The main method is to use pressure to transfer the pattern to the surface of the mooncake box paper. Through the embossing process to produce relief effect, so that the moon cake box packaging more beautiful theme more vivid, more rich touch.

Coating technology

Mooncake box after the film surface more stain resistance, water resistance, wear resistance, smooth, bright, the surface color will become more bright and beautiful, not easy to wear, mooncake box wear resistance, folding resistance, tensile and moisture resistance are better, enhance and beautify the mooncake box surface appearance effect.

Die cutting and indentation process

Die-cutting indentation process is a commonly used process in the mooncake box packaging prints, this process can be according to the design requirements of the mooncake box product design pattern with a die-cutting knife die cut into the required shape or mark forming process, so that the mooncake box packaging can express the meaning of Mid-Autumn Festival reunion to people.

Hot stamping process

Mooncake box paper stamping has the characteristics of clear pattern, beautiful, bright colors, etc., in the mooncake box packaging stamping, can play a role in highlighting the mooncake box design theme of beautification products.

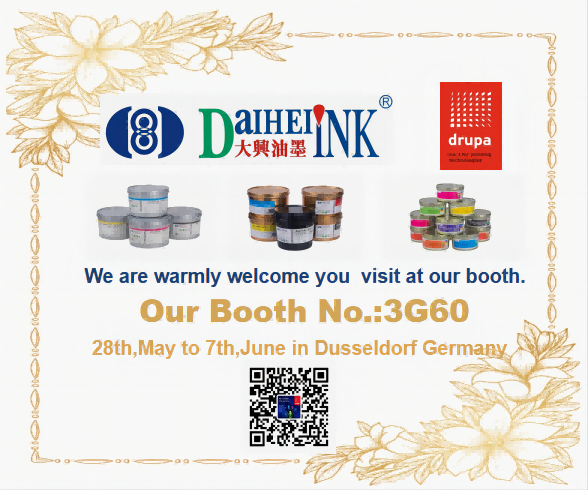

As a professional ink manufacturer, Daihei Ink is happy to add more colors to the world, show professionalism, and make the world more wonderful!

Here Daihei ink also in advance wish all the new and old friends at home and abroad happy holidays, happy reunion, business is booming!

Read More

Pure Vegetable Oil Voc Free Sheet Fed Offset Ink

Pure Vegetable Oil Voc Free Sheet Fed Offset Ink

China printing and equipment import and export data from January to December 2023

China printing and equipment import and export data from January to December 2023

Introducing UV Pantone High Concentration Ink

Introducing UV Pantone High Concentration Ink

The Mid-Autumn Festival

The Mid-Autumn Festival

Why need spot color printing?

Why need spot color printing?

MOAH and MOSH: Understanding Potential Contaminants in Food

MOAH and MOSH: Understanding Potential Contaminants in Food

Who is really love earth?

Who is really love earth?

Ink history

Ink history

VOC Free offset ink era is coming

VOC Free offset ink era is coming